Add to Cart

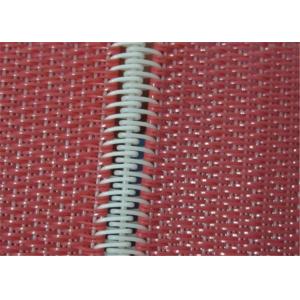

Paper Machine Clothing Flat Surface Polyester Weave Dryer Fabric For Paper Making

Weave Dryer Fabric Description

The dryer screen dries the paper web after passing a press section by adhering the web to a steam-heated cylinder.

In the dryer section of the paper machine, the paper sheet travels around large-diameter heated cylinders, remaining water is removed by evaporation.

The screen is characterized by a smooth surface and seam, the stable structure gives more resistance to distortion, good runnability reduces sheet flutter and breaks, contamination resistance and easy cleaning for good using life and maintains even permeability and other advantages.

Woven dryer screen can be divided into 3-shed, 4-shed & 8-shed. Made from high-grade flat monofilament and round monofilament polyester yarns. Used in the dryer section of paper machine to produce newsprint paper, writing paper, carbonless paper, copper print, etc.

Weave Dryer Fabric Seam Type: Insert, Pin, Ping ring, Spiral ring join.

Weave Dryer Fabric Technical parameters

| FABRIC CODE | WEFT DENSITY | WARP DENSITY | WARP DIAMETER | WEFT DIAMETER | AIR PERMEABILITY |

| HT22604-1 | 23.0~24.0 | 14.5~15.5 | 0.815 X 0.31 | 0.40, 0.60 | 90CFM |

| HT22604-2 | 23.0~24.0 | 13.0~14.0 | 0.815 X 0.31 | 0.40, 0.60 | 150CFM |

| HT22604-3 | 23.0~24.0 | 11.5~12.5 | 0.815 X 0.31 | 0.40, 0.60 | 250CFM |

| HT18504 | 18.5~19.5 | 15.5~16.5 | 0.58 X 0.38 | 0.60 | 150CFM |

| HT18504-2 | 18.5~19.5 | 10.5~11.5 | 0.58 X 0.38 | 0.70 | 600CFM |

Weave Dryer Fabric Product Pictures: