Add to Cart

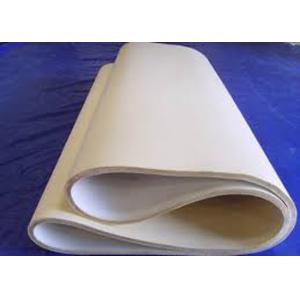

8mm Thickness High Temp Resistance Nomex Blanket 100% Nomex For Textile Finishing Machine

DESCRIPTION

The Calendering Felts For Compacting Machines is used in compactor machines. Made by blending of the Nomex, polyester, and wool, the Calendering Felts For Compacting Machines are used in shrinkage of the knitted fabrics and the size is made according to the customers' request.

The Compacting Felt is used in compactor machines. Made by blending of the Nomex, polyester, and wool, the Needled Endless Compacting Felt is used in shrinkage of the knitted fabrics and the size is made according to the customers' request.

SPECIFICATION

| Material | Nomex, Polyester, Wool, Nylon |

| Temperature | 210°c ~ 260°c,160°c~200°c,until160°c |

| Colors | light yellow, white |

| Density | 8800g/m2-9800g/m2 |

| Function | belt conveyor |

| Place of Origin | China |

| Payment Terms | T/T Payment |

| Package | PE bags |

| MOQ | 1 PC |

| Delivery Time | within 15 days delivery after receipt your payment |

Thickness: 7-8mm,10-11mm

Width: 600-4000mm

The perimeter: 2200mm, 2600mm, 3400mm, 5000mm or as your demands

All of the Nomex Printing Belt could do as your requirement, kindly let me know your demands about the size you need if you have interesting about our products.

Product Structure:

100% Nomex + endless polyester base fabric, Endless design to meet your transfer printing needs.

Product Advantage:

1. 100% Nomex raw material

2. The max temperature resistant 250℃

3. Endless type - no joint(Don't worry about the fracture)

4. Misaligned----Our base cloth is used endless industrial silk. The testing report showed the misaligned rate is about ±3mm. enclosed our base cloth for your consideration

5. Shrinkage----The base cloth can control the shrinkage rate by 2.5%--3%.

APPLICATION

Our high-temperature digital printing blanket is used for all kinds of heat transfer machines, large printing factories, large scale factories and so on.

Calendering Felts For Compacting Machines is used on the following machines: Ferraro, Monti Muzzi, Sautex, Sperotto, Poongkwang, Monforte, Lafer, etc.

Package&Delivery

Package: plastic bag+carton

Delivery: Express company & by air & by sea or as your demands

FAQ

1. How long it can be used?

It depends on your scale of production and your use custom.

2. The Sample is free?

Yes, if you need the samples, we will send it to you freely. but I hope you pay the freight. thank you.

3. What is the lead time?

About 7 working days.

4. What is packing?

By air & by sea or as your demands

How to solve the problem of deviation of the thermal transfer banner machine felt?

1 make the belt tight, back when not in use( or back when the temperature drops)

2 Reduce the pressure on the pressure roller