High - Speed And Energy - Efficient Crecent Former Tissue Paper Machine

Technical Specification Sheet

- Product : toilet paper , towel paper , tissue paper

- Raw material : wood pulp , bamboo pulp and so on

- Grammage : 12-45 g/㎡

- Trim width : 3600 mm

- Working speed : 600-800m/min ( dryer line speed )

- Designing speed : 1000m/min ( dryer line speed )

- Creping ratio :28%

- Capacity : 39t/d ( calculated by 700m/min dryer line speed , grammage 15 g/㎡, creping ratio 28% )

- Gauge : 3800mm-3900mm

- Drive method : sectional drive , AC frequency control

- Installed capacity : 263.5kw ( accessory motor not included )

- Dimension : 18000*10500*7000mm ( L*W*H)

- Max reeling diameter : 2000mm

Configuration Introduction :

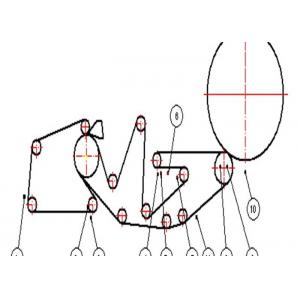

- This machine is middle speed crescent former tissue paper machine with single felt , single wire and multi drive point . consists of forming section , press section , dryer section , reeling section , drive section , foundation section , control system and so on .

- Forming section include : head box , forming roll , water tray , wire part , inside white water tank , guide roll and cleaning doctor .

- Press and dryer section includes one set Φ3330mm yankee dryer , one set touch roll , one set felt circle , frame and so on . suction touch roll adopts air bag pressurized . one set felt circle connect with forming section , equips with pneumatic guider , electrical stretcher , guide roll , high pressure oscillating spray pipe , low pressure sector spray pipe and felt cleaning device . dryer adopts rolling bearing , equips with lubrication system , recycling lubrication .

- Hot wind recycling breath type hood , can finish approx 40% drying capacity . hood consists of dry and wet section , both are open type , easy to clean .

- Consists of forming roll , dryer and reeling machine three drive point . forming roll drive is hardened reduce equips with cardan shaft , dryer drive is hollow shaft reduce , reeling machine is hardened reduce . forming section and dryer are independent drive , easy to clean felt wire and for dryer pre-heating .

- Reeling machine consists of reeling drum , reeling drum doctor , main arm system , accessory arm system , accessory arm drive system , arc roll spread device , frame and so on . reeling drum adopts coupler , equips with AC motor , YZL hardened reduce drive method .

-

| Item / PM type | 1575 | 1880 | 2400 | 2900 | 3500 | 3900 |

| Design Speed (m/min) | 250 | 250 | 250 | 250 | 250 | 250 |

| Working Speed (m/min) | 160-230 | 160-230 | 160-230 | 160-230 | 160-230 | 160-230 |

| GSM Range (g/m2) | 13-30 | 13-30 | 13-30 | 13-30 | 13-30 | 13-30 |

| Capacity | 4-6 | 5-8 | 7-10 | 8-12 | 10-15 | 11-18 |

| Diameter of Dryer (mm) | Φ2500-3000 | Φ2500-3000 | Φ2500-3000 | Φ2500-3000 | Φ2500-3000 | Φ2500-3000 |

| Motor (kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 90-110 |

| Gauge(mm) | 2400 | 2800 | 3400 | 3900 | 4500 | 4800 |

-